The Science Behind Wind Turbine Blade Design and Efficiency

23 February 2025

Wind turbines are becoming more and more common in our daily lives. Whether you’re driving through the countryside or gazing out over a coastal horizon, you’ve probably seen those massive white wind turbines silently spinning against the sky. But have you ever stopped to wonder how those blades are designed? Why are they shaped the way they are? And what makes them so efficient at capturing wind energy?

In this article, we’ll dive into the fascinating science behind wind turbine blade design and efficiency. By the end of it, you’ll have a better understanding of why wind energy is such a promising renewable energy source and how those blades play a crucial role in making it all happen.

Why Blade Design Matters

Let’s start with the basics: why is the design of the blades so important? Well, wind turbines work by capturing the kinetic energy from the wind and converting it into electricity. The blades are the first point of contact with the wind, so their design directly impacts how much energy can be harvested.Imagine you’re trying to catch rain in a bucket. If the bucket is too small or has holes in it, you won’t collect much water, right? The same logic applies to wind turbines. If the blades aren’t designed properly, they won’t capture enough wind energy, leading to inefficiency. And in the world of renewable energy, efficiency is everything.

But here's the thing—designing a wind turbine blade isn't as simple as making it bigger or longer. There's a lot more science involved, and it all starts with understanding aerodynamics.

Aerodynamics: The Key to Blade Efficiency

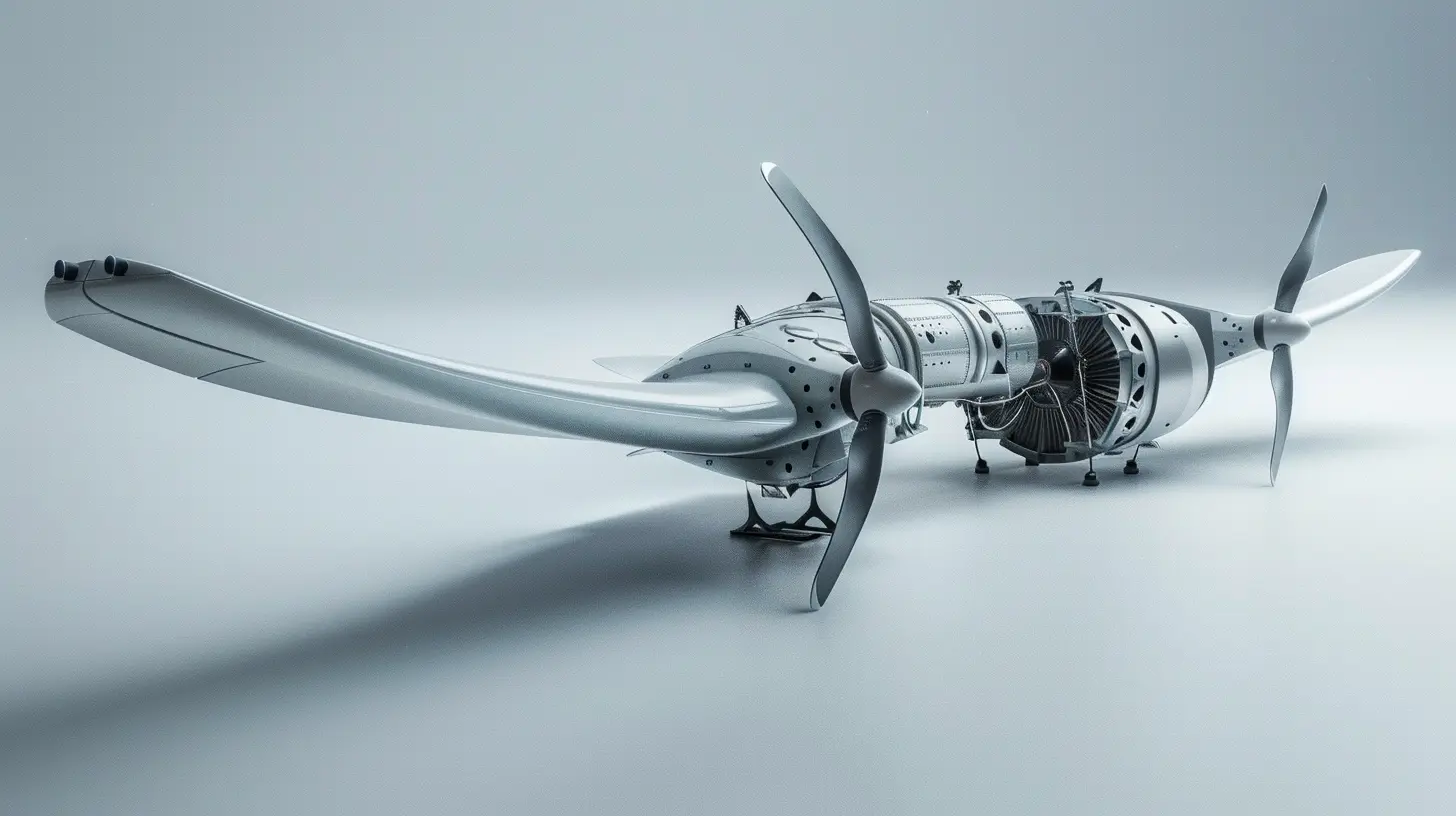

At its core, wind turbine blade design is all about aerodynamics. The goal is to create blades that can slice through the air with minimal resistance while maximizing the amount of energy they extract from the wind. This is where things get interesting.Lift and Drag: The Balancing Act

The concept of lift and drag is fundamental to aerodynamics. Lift is the force that pushes the blade upwards (or in the case of a turbine, forwards), while drag is the force that slows it down. The secret to efficient wind turbine blades is maximizing lift while minimizing drag. Think of it like riding a bike downhill—you want to go as fast as possible without getting slowed down by wind resistance.Wind turbine blades are designed similarly to airplane wings. They have an airfoil shape, which means they’re curved on one side and flat on the other. This shape helps create a pressure difference as wind flows over the blade, generating lift. The more lift you generate, the faster the blades spin, and the more energy you can capture.

However, too much drag can ruin the party. If the blades create excessive drag, they’ll encounter more resistance, slowing them down and reducing efficiency. The challenge for engineers is finding the sweet spot where lift is maximized, and drag is minimized. It’s a delicate balancing act, but when done right, it can significantly boost the turbine’s performance.

Angle of Attack: Finding the Right Tilt

Another critical factor in wind turbine blade design is the angle of attack. This refers to the angle at which the wind hits the blade. If the angle of attack is too steep, the blade will create too much drag, and if it’s too shallow, it won’t generate enough lift.The ideal angle of attack changes along the length of the blade. Near the root (where the blade attaches to the hub), the angle is usually steeper to handle the lower wind speeds near the center of the turbine. As you move towards the tip of the blade, the angle becomes shallower to accommodate the higher wind speeds at the outer edge.

Finding the right angle of attack for every section of the blade is a bit like tuning a musical instrument. If one part is off, the whole system doesn’t perform as well. But when everything is in harmony, the turbine can extract the maximum amount of energy from the wind.

Blade Length: Bigger Isn't Always Better

It might seem logical that longer blades would capture more wind and generate more energy, but it’s not that simple. While longer blades can indeed harvest more energy, they also come with trade-offs.First, longer blades are heavier. This means the turbine needs a stronger, more expensive tower to support the added weight. Additionally, longer blades experience higher forces, which can lead to increased wear and tear. Maintenance costs go up, and the turbine’s lifespan might be shortened if the blades aren’t built to withstand these forces.

Another factor to consider is wind speed. Wind turbines are usually located in areas with relatively consistent wind patterns, but even then, wind speeds can vary. If the blades are too long, they might not perform well in lower wind conditions. On the other hand, shorter blades are more suited for lower wind speeds but might not capture enough energy in high-wind scenarios.

So, while it’s tempting to go bigger, blade length must be carefully optimized for the specific location and wind conditions where the turbine will operate. It’s all about finding the right balance between size, weight, and performance.

Blade Materials: Strength Meets Flexibility

You might be wondering, what are these giant blades made of? The answer is a combination of lightweight and strong materials that can withstand the forces they encounter while spinning at high speeds.Most modern wind turbine blades are made from composite materials, typically a combination of fiberglass and epoxy resin. These materials are great because they’re both strong and lightweight. Blades made from heavier materials would require more energy to turn and would put extra stress on the turbine’s components.

But strength isn’t the only consideration. Wind turbine blades also need to be flexible enough to bend slightly in strong winds without breaking. This flexibility allows them to absorb some of the wind’s energy without snapping under pressure. Think of a tree swaying in the wind—it can move back and forth without breaking because it’s flexible. Wind turbine blades work in a similar way.

In recent years, engineers have been experimenting with new materials like carbon fiber, which is even lighter and stronger than fiberglass. While carbon fiber is more expensive, it offers the potential for longer, more efficient blades that can capture more wind energy.

Blade Shape: The Twist That Makes a Difference

If you’ve ever seen a wind turbine up close, you might have noticed that the blades aren’t flat—they have a slight twist. This twist is essential for optimizing the blade’s efficiency.Remember how we talked about the angle of attack earlier? The wind speed varies along the length of the blade, so the angle of attack needs to change accordingly. By twisting the blade, engineers can ensure that each section is always at the optimal angle to capture the most energy from the wind.

The twist also helps reduce the risk of stalling, which happens when the blade loses lift and stops generating power. Stalling can occur if the angle of attack becomes too steep, especially in high-wind conditions. The twist helps distribute the forces more evenly along the blade, reducing the chances of stalling and ensuring smooth operation.

The Role of Blade Optimization in Energy Production

Now that we’ve broken down the different elements of blade design, let’s talk about the bigger picture—energy production. The overall efficiency of a wind turbine is directly tied to how well the blades are designed and optimized.A well-designed blade can significantly increase the amount of energy a turbine generates over its lifetime. In fact, improving blade efficiency by just a few percentage points can have a massive impact on the turbine’s ability to generate power. This is why engineers are constantly researching new materials, shapes, and technologies to push the boundaries of blade efficiency.

In recent years, advancements in computational fluid dynamics (CFD) have allowed engineers to simulate how air flows over the blades in a virtual environment. This has led to the development of more complex and efficient blade designs that can capture even more wind energy.

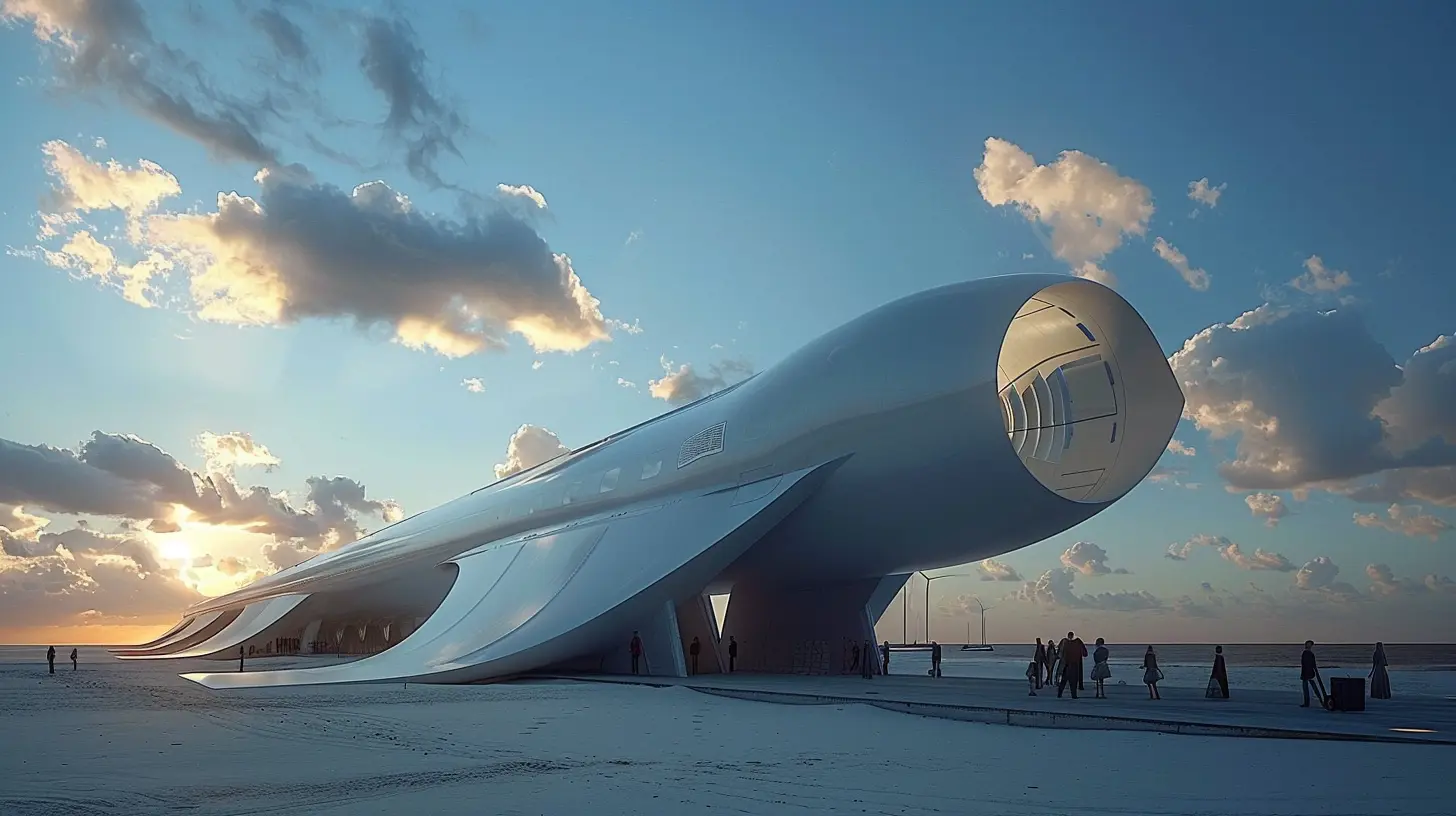

The Future of Wind Turbine Blades

As the demand for renewable energy grows, so does the need for more efficient wind turbine blades. In the future, we can expect to see even longer blades made from advanced materials like carbon fiber. These blades will be lighter, stronger, and more efficient, allowing turbines to generate more power from the same amount of wind.We might also see the development of smart blades, which can automatically adjust their shape or angle in real time to maximize efficiency based on wind conditions. These blades could use sensors and artificial intelligence to make split-second adjustments, ensuring that the turbine is always operating at peak performance.

Additionally, we could see more offshore wind farms, where turbines are placed out at sea, where wind speeds are higher and more consistent. Offshore turbines can have much larger blades than their onshore counterparts, further increasing energy production.

Conclusion: Blades Are the Heart of Wind Energy

In the world of wind energy, blades are the unsung heroes. They may look simple from a distance, but their design is the result of years of research and engineering. From aerodynamics to materials science, every aspect of blade design plays a critical role in determining how much energy a wind turbine can generate.As technology continues to advance, we can expect even more efficient and innovative blade designs in the future. And as we move towards a cleaner, more sustainable energy future, wind turbines—and their blades—will be at the forefront of that transition.

all images in this post were generated using AI tools

Category:

Renewable EnergyAuthor:

Michael Robinson

Discussion

rate this article

20 comments

Atlas McNeil

Understanding the science of wind turbine blade design is crucial for maximizing efficiency and harnessing renewable energy effectively. Continuous innovation in aerodynamics and materials is key to optimizing performance and driving the future of sustainable energy solutions. Let's invest in this technology.

April 7, 2025 at 4:47 AM

Michael Robinson

Thank you for your insightful comment! I completely agree—innovation in aerodynamics and materials is vital for enhancing wind turbine efficiency and advancing renewable energy solutions. Your support for investing in this technology is essential for a sustainable future!

Ardent McAlister

Could hidden algorithms be reshaping the future of renewable energy? Discover the secrets within.

April 3, 2025 at 11:31 AM

Michael Robinson

Absolutely! Hidden algorithms can optimize turbine blade design and enhance efficiency by analyzing data on wind patterns and material performance, ultimately shaping a more sustainable energy future.

Shelby McVey

Who knew wind turbines had such a 'blade' for design? If only my hair would catch the wind as efficiently—maybe I'd be the next eco-hair model!

March 31, 2025 at 3:27 AM

Michael Robinson

Thanks for the clever comment! Wind turbine blades are indeed designed for efficiency—maybe we should take some notes for eco-friendly hairstyles!

Elin McLemore

Who knew wind turbines had more design finesse than my last haircut? If only they could catch those dad jokes blowing around—imagine the energy we’d generate from laughter alone! Let’s harness that next!

March 28, 2025 at 3:46 AM

Michael Robinson

Thanks for the clever comment! Harnessing laughter would definitely add a fun twist to renewable energy discussions!

Aleta Lozano

Great article! It’s fascinating to see how science and engineering come together in wind turbine design. Efficiency really does make a difference for our planet!

March 27, 2025 at 7:42 PM

Michael Robinson

Thank you! I'm glad you found it fascinating. The synergy between science and engineering is indeed crucial for advancing sustainability in wind energy!

Camden Rocha

This article brilliantly unravels the intricate science behind wind turbine blade design, highlighting the crucial balance between aerodynamics and material efficiency. Understanding these principles is essential for advancing renewable energy technologies and maximizing the potential of wind power in our sustainable future.

March 27, 2025 at 3:59 AM

Michael Robinson

Thank you for your insightful comment! I'm glad you found the article helpful in understanding the complexities of wind turbine blade design and its impact on renewable energy.

Otis Collins

This article offers fascinating insights into the intricate world of wind turbine blade design! I’m intrigued by how aerodynamics and material science converge to enhance efficiency. It's amazing to think how this innovation could reshape our energy landscape. Looking forward to more on sustainable tech advancements!

March 25, 2025 at 4:45 AM

Michael Robinson

Thank you for your insightful comment! I'm glad you found the article engaging and appreciate your enthusiasm for sustainable tech advancements!

Camden Brooks

Incredible insights on how innovation drives renewable energy! Understanding the science behind wind turbine blade design not only enhances efficiency but also empowers us to harness nature's power for a sustainable future. Let's embrace technology for a greener tomorrow!

March 24, 2025 at 7:27 PM

Michael Robinson

Thank you for your insightful comment! I'm glad you found the discussion on wind turbine blade design both engaging and important for a sustainable future. Let's continue to embrace innovation in renewable energy!

Dean Benton

Ah, the riveting world of wind turbine blade design! Who knew that optimizing a piece of glorified plastic could be so electrifying? Next, let’s dive into the thrilling saga of paperclips—because who wouldn’t want to read about the science of efficient paper organization?

March 23, 2025 at 1:14 PM

Michael Robinson

I appreciate your humor! While it may seem niche, optimizing wind turbine blades is crucial for renewable energy efficiency and sustainability. Every bit counts in the fight against climate change!

Audra Stewart

This article beautifully demystifies the complex world of wind turbine blade design. I appreciate the clear explanations and insights into optimizing efficiency—it's inspiring to see how science drives sustainable energy solutions.

March 22, 2025 at 11:28 AM

Michael Robinson

Thank you for your kind words! I'm glad you found the article insightful and inspiring. Sustainable energy solutions are indeed a fascinating field!

Runehart Ramirez

This article brilliantly simplifies the complex science of wind turbine blade design. Understanding aerodynamics and material efficiency is crucial for enhancing renewable energy. The insights on optimizing blade shape for performance are particularly valuable. It's crucial for the industry to keep innovating to maximize energy capture and reduce costs. Great read!

March 20, 2025 at 8:53 PM

Michael Robinson

Thank you for your kind words! I'm glad you found the article valuable in understanding wind turbine blade design and its impact on renewable energy. Your support for innovation in this field is appreciated!

Lillian Myers

What a fascinating exploration of wind turbine technology! 🌬️⚡ It's exciting to see how innovative blade designs enhance efficiency and harness renewable energy. This article beautifully highlights the intersection of science and sustainability. Cheers to a greener future powered by smart engineering! Keep up the fantastic work!

March 20, 2025 at 4:52 AM

Michael Robinson

Thank you for your kind words! I'm glad you enjoyed the article and share the excitement for innovation in renewable energy. Cheers to a sustainable future! 🌱✨

Wesley Roberson

This article effectively highlights the intricate balance between aerodynamics and material science in wind turbine blade design. However, a deeper exploration of the environmental impact of manufacturing these materials could further enhance the discussion on sustainability in renewable energy.

March 17, 2025 at 5:55 AM

Michael Robinson

Thank you for your valuable feedback! I appreciate your suggestion on exploring the environmental impact of material manufacturing, and I will consider it for future discussions on sustainability in wind turbine technology.

Thea Meyers

Harnessing the power of the wind through innovative turbine blade design is not just about efficiency; it's a revolution in sustainable energy. As technology advances, we pave the way for a cleaner, greener future. Let's embrace the winds of change together!

March 11, 2025 at 1:20 PM

Michael Robinson

Thank you for your insightful comment! I completely agree that innovative turbine blade design is key to advancing sustainable energy and creating a cleaner future. Together, we can indeed harness the winds of change!

Blair Bailey

Great article! I appreciate the insights into the engineering behind wind turbine blades. Understanding the balance between aerodynamics and materials is crucial for improving efficiency. Looking forward to more discussions on innovations that could further enhance renewable energy solutions!

March 9, 2025 at 5:18 AM

Michael Robinson

Thank you for your thoughtful comment! I'm glad you found the insights valuable. Stay tuned for more discussions on innovations in renewable energy!

Celine Elliott

Wind turbine blades: the ultimate blend of science and sass! Who knew that aerodynamic curves could be so sexy? Let’s just hope they can keep up with my high standards for efficiency. 🌬️💁♀️

March 7, 2025 at 11:43 AM

Michael Robinson

Glad you appreciate the design! The fusion of science and aesthetics in wind turbines truly elevates their efficiency and appeal. 🌬️✨

Kane Wood

Fascinating read! It's amazing how science and creativity come together in wind turbine blade design. Every turn of those blades is a step toward a cleaner future. Keep up the great work, tech innovators!

March 5, 2025 at 8:26 PM

Michael Robinson

Thank you for your kind words! We're thrilled to share the intersection of science and creativity in wind turbine blade design. Together, we're shaping a sustainable future!

Cerys Lawson

Insightful exploration of design factors impacting wind turbine efficiency!

March 4, 2025 at 11:35 AM

Michael Robinson

Thank you! I'm glad you found the exploration insightful. Your feedback is much appreciated!

Mika Weber

This article succinctly unveils the intricate balance between aerodynamics and materials science in wind turbine blade design, highlighting how advancements can significantly enhance efficiency and drive the renewable energy agenda forward.

February 24, 2025 at 8:40 PM

Michael Robinson

Thank you for your insightful comment! I'm glad you found the article effective in highlighting the critical relationship between aerodynamics and materials science in optimizing wind turbine blade design.

Christina Klein

Great insights on design!

February 23, 2025 at 1:35 PM

Michael Robinson

Thank you! I'm glad you found the insights valuable.

MORE POSTS

How to Optimize Your Workflow Using Collaborative Content Tools

Blockchain for Renewable Energy Trading: A Greener Future

Blockchain vs. Quantum Computing: Are We Ready for the Future?

The Best E-Readers for Book Lovers on the Go

How the Metaverse Could Shape the Future of Competitive Gaming

How Smart Cities Are Integrating Green Technology

Blockchain and the Art World: NFTs and Digital Ownership

How to Choose the Perfect Lens for Your Digital Camera

The Role of Green Technology in Fighting Climate Change

How to Build a Tech Startup That Attracts Top Talent

Advanced Wearable Devices for People with Disabilities: Empowering Independence

Health and Fitness Gadgets for the Active Traveler